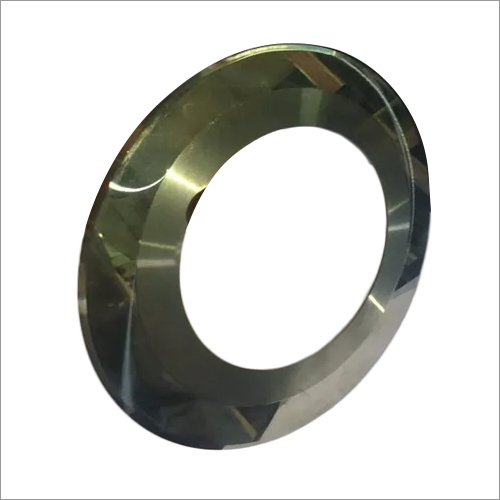

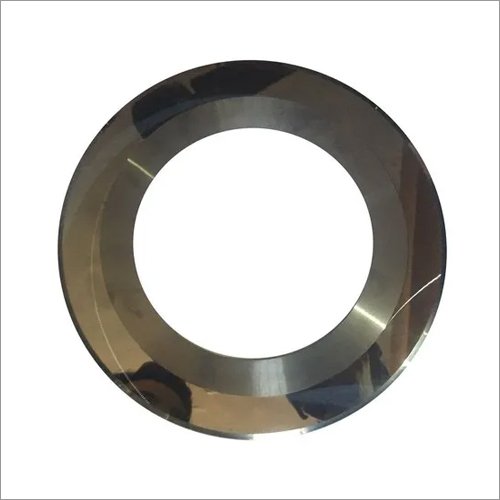

Hybrid Bond Diamond Wheel

Product Details:

- Application Precision Grinding

- Size 75-400 mm

- Bond Type Hybrid Bond

- Click to View more

Hybrid Bond Diamond Wheel Price And Quantity

- 28 INR/Piece

- 1 Piece

Hybrid Bond Diamond Wheel Product Specifications

- 75-400 mm

- Precision Grinding

- Hybrid Bond

Hybrid Bond Diamond Wheel Trade Information

- Ex. Works Vadodara

- 10000 Piece Per Month

- 15 Days

- Yes

- Contact us for information regarding our sample policy

- Corrugated Box

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

A unique kind of grinding wheel known as a hybrid bond diamond wheel combines the qualities of both resin bond and metal bond wheels. It is made with the intention of providing the benefits of both bond types for particular grinding applications.

Hybrid bond wheels are typically used for grinding fragile, hard materials including glass, ceramic, and some kinds of composites. They are especially well suited for tasks requiring rapid material removal rates, enhanced cutting efficiency, and prolonged wheel life.

These wheels' hybrid bonds are produced by combining a resin bond with metal bond components, such bronze or copper. Incorporating the advantages of both bond types, this combination creates a special bond matrix.

The following are some of the main traits and benefits of hybrid bond diamond wheels:

1. Cutting performance: Compared to resin bond wheels, hybrid bond wheels offer better cutting performance. Faster material removal is made possible by the metal bond components, which offer improved bond strength and greater grinding efficiency.

2. Wheel life: The metal bond components in hybrid wheels help the wheels last longer and wear less quickly. Longer grinding intervals and less downtime for wheel replacement follow from this.

3. Heat dissipation: Compared to pure resin bond wheels, hybrid bond wheels have greater heat dissipation capabilities. The metal bond components aid in heat dissipation during grinding, lowering the possibility of workpiece thermal damage.

4. Versatility: By modifying the ratio of resin bond to metal bond, hybrid bond diamond wheels can be fitted to particular grinding applications. Optimal performance and compatibility with various workpiece materials are made possible by this versatility.

5. Surface finish: Hybrid bond wheels can produce both exceptional surface finishes and rapid rates of material removal. The wheel's ability to create fine surface finishes with little surface roughness is made possible by the combination of resin bond and metal bond parts.

It is crucial to remember that the specific characteristics and effectiveness of hybrid bond diamond wheels might change based on the wheel's construction and design. To choose the best hybrid bond wheel for your unique grinding application, it is advised to speak with the manufacturer or supplier.

Hybrid bond diamond wheels should be used with the same safety measures as any other grinding wheel, including wearing the correct personal protection equipment (PPE) and abiding by the operating parameters, speeds, and treatment instructions specified by the manufacturer.

In conclusion, hybrid bond diamond wheels offer greater cutting performance, longer wheel life, and superior surface finishes by combining the benefits of resin bond and metal bond wheels. They are frequently utilised in precision grinding applications that need high material removal rates and prolonged wheel life because they are well-suited for grinding hard and brittle materials.

Other Products in 'Hybrid Bond Diamond Wheel ' category

|

ABAJ CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |